How to maintain the three-dimensional measuring instrument

-

2020-12-25

2020-12-25 -

The three-dimensional measuring instrument is a kind of precision measuring instrument, so regular maintenance is one of the protection methods for the three-dimensional measuring instrument. Moreover, if the maintenance is done in time, the service life of the machine can be prolonged and the accuracy of the three-dimensional measuring instrument can be well guaranteed, which reduces the failure rate. To enable customers to better grasp and use the three-dimensional measuring instrument. Let's talk about the maintenance of the three-dimensional measuring instrument in detail below.

Preparation before starting up:

1. The three-dimensional measuring instrument has strict environmental requirements, and the temperature and humidity should be strictly controlled according to the contract requirements;

2.The three-dimensional measuring instrument uses an air bearing, which theoretically never wears out the structure, but if the air source is not clean, there is oil. Water or impurities will cause blockage of the air bearing, and in severe cases, the air bearing and the air bearing guide will be scratched, with serious consequences. So check the air source of the machine tool every day, and drain water and oil. Clean the filter and oil-water separator regularly. It should also be noted that the machine air supply pre-air source (air compressor or a central gas supply tank) also regularly check;

3. The guide rail of the three-dimensional measuring instrument has a high machining accuracy, and the gap with the air bearing is very small. If there is dust or other impurities on the guide rail, it is easy to cause scratches on the air bearing and the guide rail. Therefore, the guide rails of the machine should be cleaned each time before starting the machine. Metal guide rails should be wiped with aviation gasoline (120 or 180 gasoline), and granite guide rails should be wiped with absolute ethanol.

4. Remember that no grease of any nature can be applied to any guide rail during maintenance;

5.Regularly rod, screw, rack small amount of anti-rust oil;

6. When the three-dimensional measuring instrument has not been used for a long time, preparations should be made before starting: control the temperature and humidity in the room (more than 24 hours), and in the humid environment of the south, the electric control cabinet should be opened regularly to make the circuit board It is also fully dried to avoid damage to the electronic control system due to sudden power-on after being damp. Then check whether the air source and power supply are normal;

7.Check the power supply before starting the machine. If possible, configure a regulated power supply. Check the grounding regularly. The grounding resistance is less than 4 ohm.

At the same time, we need to pay attention to the voltage of the three-dimensional measuring instrument when using it to prevent excessive voltage or sudden power failure from damaging the logic circuit board; if the machine fails, do not turn it on blindly, and must perform the problem under the guidance of a professional maintenance engineer Judgment and processing.

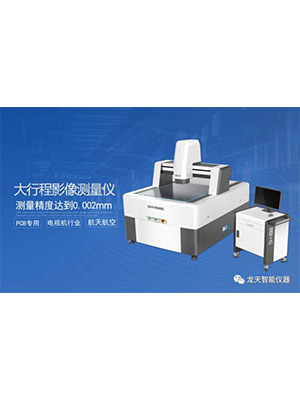

Guangdong Longtian Intelligent Instrument is a manufacturer of two-dimensional measuring instruments, three-dimensional measuring instruments, and one-button image measuring instruments. It is committed to providing better quality automatic image measuring instruments and imagers, and has a higher brand in the domestic and foreign markets Reputation!